Products

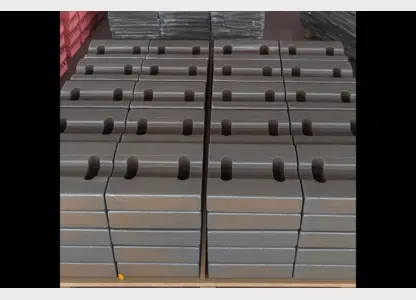

Primary Impact Crusher Liners and Manganese Castings

Secondary Impact Crusher Liners and Manganese Castings

Tertiary Impact Crusher Liners and Manganese Castings

Vertical Shaft Impact Crusher Wear Parts and Anvils

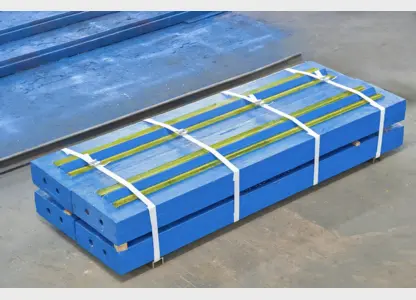

Jaw Crusher Manganese Jaw Plates, Fixed and Side Liners

DRG CRUSHER

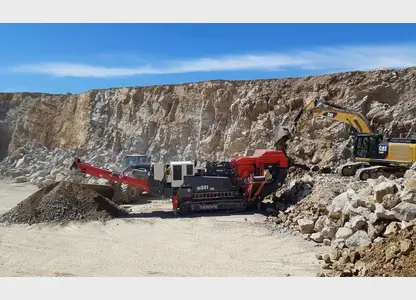

DRG CRUSHER – Your Strong Solution Partner in Industrial Casting and Spare Parts Production

DRG Makina is a casting company specialized in the production of spare parts for crushers, mainly jaw plates, impact crusher pallets, hammers, and other wear parts.

Our production combines the durability and quality required by the industry with high manganese and chromium alloyed steels.

We offer custom casting solutions and technical drawing support tailored to customer requirements.

Sandvik, Metso, Kleemann, Terex, and Hazemag Blow Bars, Jaw Plates, and Wear Liners

Blow bars, jaw plates, and wear liners for world-renowned crusher brands such as Sandvik®, Metso®, Kleemann®, Terex®, and Hazemag® are readily available in our inventory under the guarantee of DRG Crusher. These parts are manufactured from special alloys containing high levels of manganese and chrome, and their reinforced structure ensures maximum performance even under the toughest working conditions. Our heat-treated and quality-controlled castings are perfectly compatible with original parts, and their long service life and low maintenance requirements significantly enhance operational efficiency. As DRG Crusher, we offer high-strength, field-proven spare parts for both mobile and stationary crushers with the advantage of fast delivery.

Crusher Electric Motors

DRG Crusher provides high-efficiency, powerful, and durable electric motors for crusher systems, which are at the core of crushing and screening plants. The reliable operation of crushers, screens, and conveyor belts depends directly on the quality and performance of the motors used.

Our company keeps in stock electric motors fully compatible with both stationary and mobile crusher systems, available in various power, speed, and torque configurations, and designed to withstand harsh working conditions. The motors offered by DRG Crusher are CE certified, quality-tested, and proven in field applications.

From high-torque motors for crushers to optimized models for vibrating screen systems, and continuous-duty motors for conveyor belts to solutions for specific applications, we offer a wide range of products. Each motor is selected by our expert team based on the technical needs and working conditions of your system.

DRG Crusher supplies electric motors that ensure reliability, continuity, and efficiency in crushing and screening operations, delivering long service life with minimal maintenance requirements.

English

English

Le français

Le français

Türkçe

Türkçe