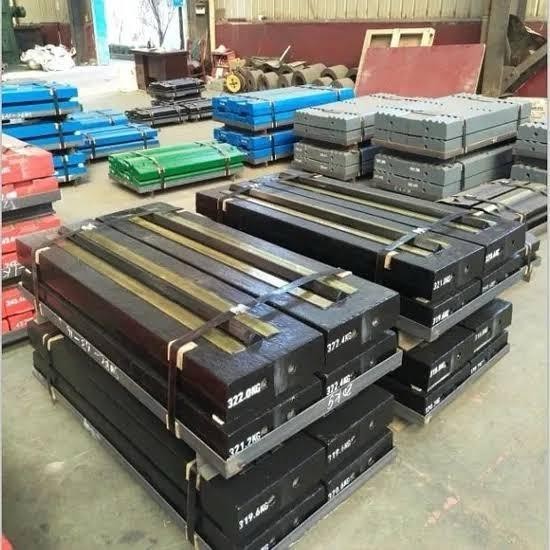

High manganese pallets and spare parts are available in our stock.

Fast contact: +90 542 666 11 11

The quality of spare parts is crucial for efficient and uninterrupted production in stone crushing plants. At DRG Makina, we combine quality and affordability in the production of high-manganese and chromium castings for stone crushing plants. With our durable, long-lasting, and highly wear-resistant parts, you can maximize the performance of your plant.

High-Manganese Castings

Manganese steels are known for their excellent resistance to impact and wear. High-manganese castings used in stone crushing plants:

Provide high resistance to impact and crushing.

Ensure long service life.

Deliver maximum performance during the crushing of hard minerals.

For this reason, high-manganese castings are preferred in jaw crushers, cone crushers, and other crushing machines.

Chromium Castings

Chromium castings provide excellent protection against wear, especially when crushing hard and abrasive stones. Higher chromium content increases hardness and provides longer service life. Key features of chromium castings include:

Superior resistance to abrasion.

Long service life under demanding conditions.

Reduction of maintenance costs.

DRG Crusher Assurance

At DRG Crusher, we are a reliable partner in the production of specialized spare parts, high-manganese castings, and chromium castings for stone crushing plants. Our products are manufactured according to quality standards and offered at competitive prices.

English

English

Le français

Le français

Türkçe

Türkçe