Spare parts and wear shields are available in our stocks.

Quick Access: +905426661111

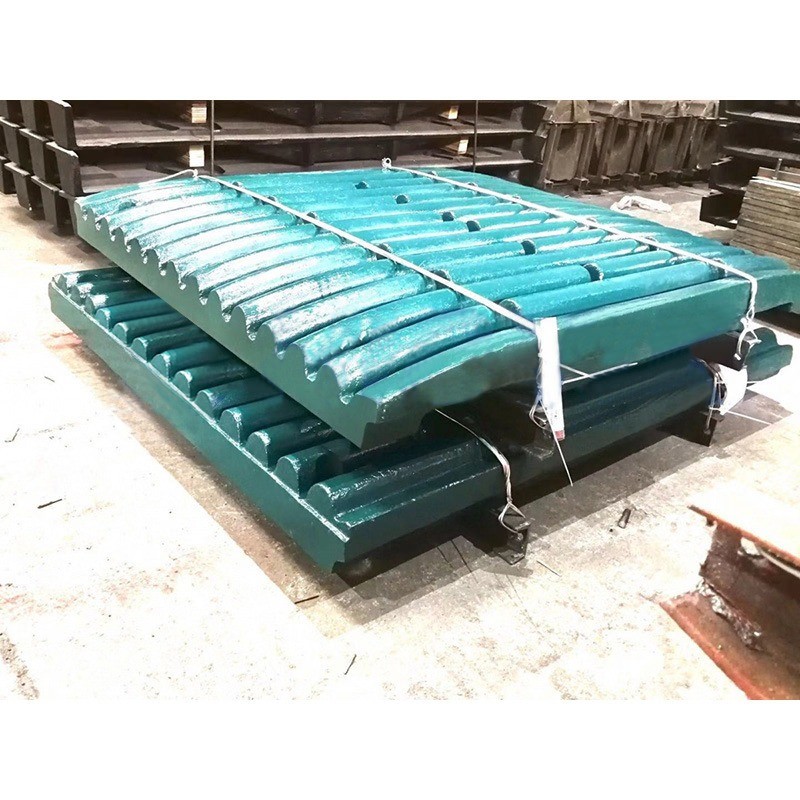

Chrome cast blow bars are essential components used in crushers to improve performance and durability. Manufactured from high-chrome alloys, these blow bars offer exceptional hardness and wear resistance, making them ideal for crushing hard and abrasive materials. The high chromium content in these blow bars forms a tough surface that protects against wear, impact, and deformation during crushing operations. This resistance significantly extends the service life of the blow bars, reducing downtime and maintenance costs for crushing plants.

In addition to wear resistance, chrome cast blow bars provide excellent corrosion resistance. This feature is particularly beneficial in environments where moisture or chemicals are present, as it prevents rust and other forms of corrosion that could weaken the blow bars and compromise crusher performance. Moreover, these blow bars maintain a balance between hardness and toughness, allowing them to absorb impact energy without cracking, which is crucial for the demanding conditions crushers often face.

Using chrome cast blow bars not only enhances crusher efficiency but also leads to lower operational costs. Although their initial purchase price may be higher compared to other materials, the longer lifespan and reduced frequency of replacement justify the investment. Overall, chrome cast blow bars are a smart choice for industries requiring reliable and cost-effective crusher components.

English

English

Le français

Le français

Türkçe

Türkçe