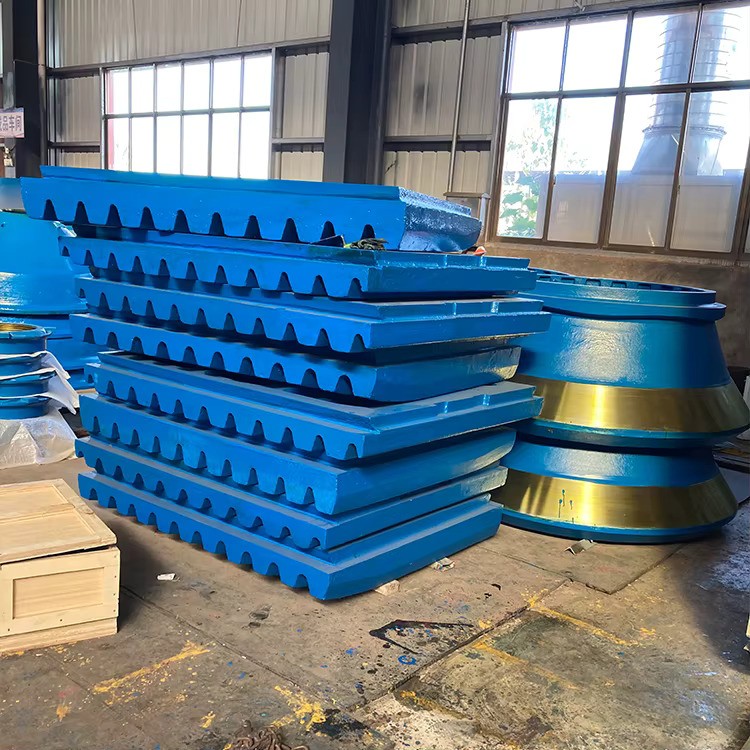

In stone crushing plants, wear liners are plates or coatings, usually made of manganese or chromium alloy steel, used to protect crusher chambers and surfaces that come into contact with materials.

What do they do?

-

Protect the crusher body from impacts and abrasion caused by stones and ore.

-

Extend machine life and reduce maintenance costs.

-

Maintain crusher performance and ensure efficient operation.

How do they work?

Wear liners are installed in crusher chambers or on surfaces that contact material. When stones or ore hit the liners, the liners absorb the impact and friction, preventing damage to the main body. Worn liners can be replaced to maintain continuous operation.

Where are they used?

-

Quarries and natural stone crushing plants (marble, granite, etc.)

-

Aggregate production plants

-

Mining ore crushing and screening facilities

-

Recycling and construction waste processing plants

English

English

Le français

Le français

Türkçe

Türkçe