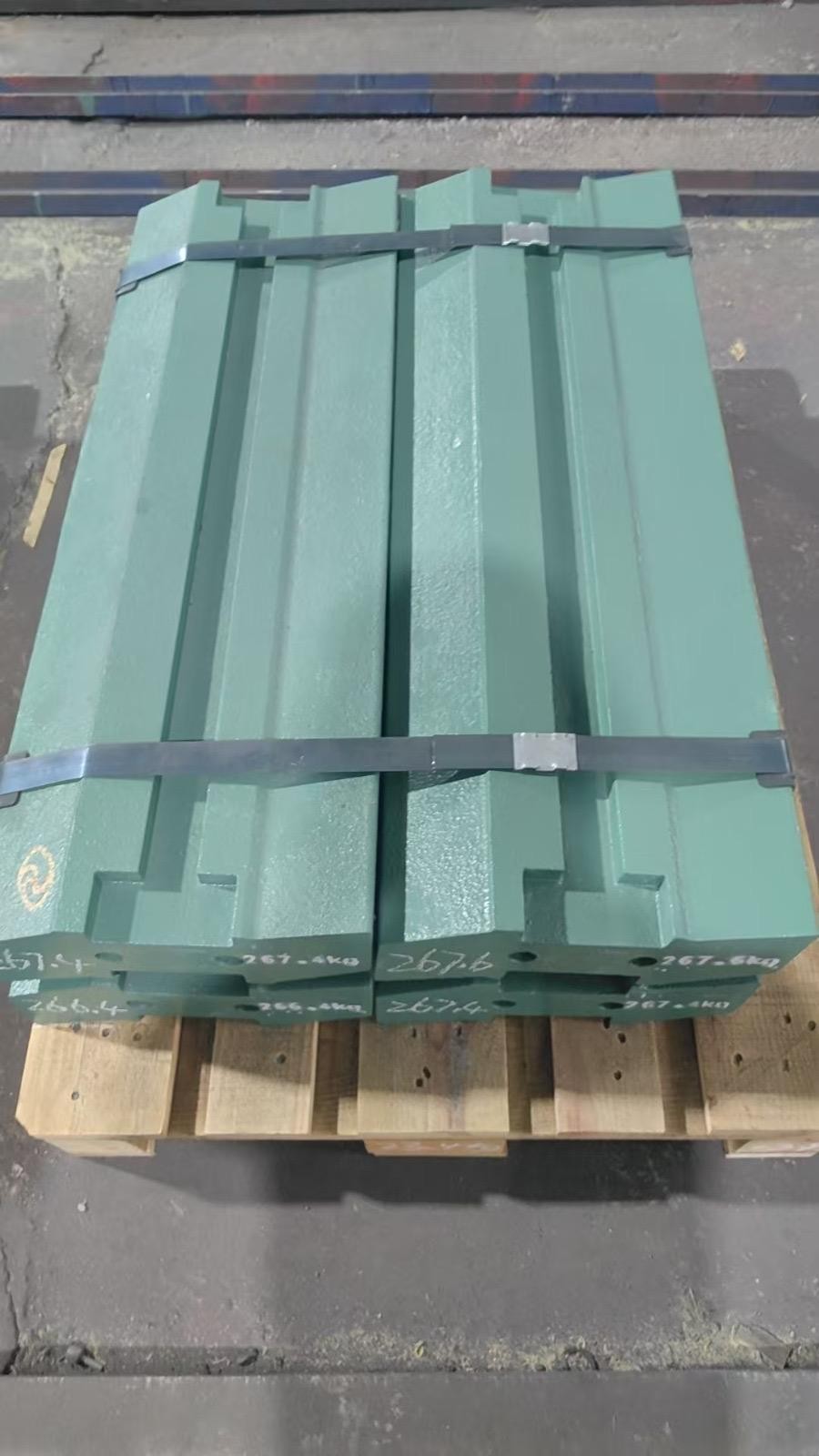

Durable High-Chrome Crusher Blow Bars

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

Durable and high quality spare parts and wear parts are available in our stockQuick Access +905426661111 Chrome cast blow bars are essential components used in crushers to improv... More Details

High manganese pallets and spare parts are available in our stock.Fast contact: +90 542 666 11 11The quality of spare parts is crucial for efficient and uninterrupted production in... More Details